Knock Outs and Block Outs Using Expanded Polystyrene (EPS) to create

A blockout is a recess at a joint gap edge to accept different types of expansion joint profiles. Also referred to by regional terminology such as knockout, cutout, and others. NOTE: The definitions of terms and terminology herein are rooted in the context of use in the field of construction-related joint sealing in EMSEAL's experience.

31 After Casting, 2Layer Longitudinal Cover Concrete Blockout Strips

What Is the Most Cost-Effective Concrete Block-Out Material? Careful planning for vertical chases in the construction of a high-rise building can save thousands of dollars in rework later in the project.

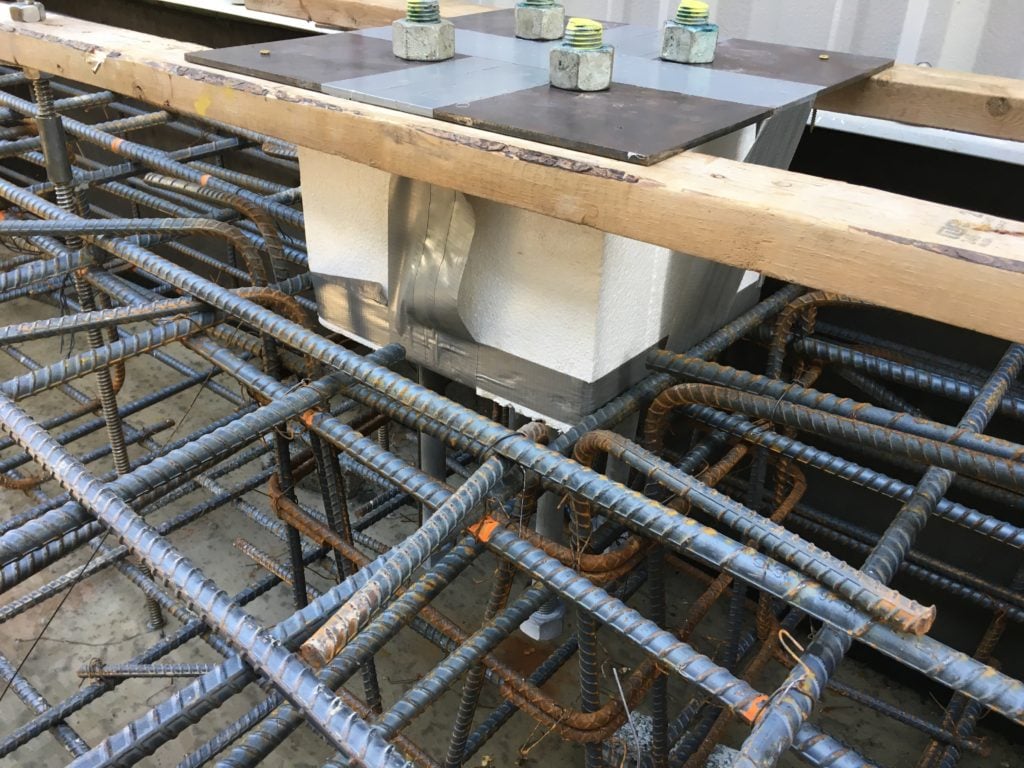

EPS Concrete blockout used to anchor prior to the concrete being

SureLedge® is a unique, lightweight, and easy-to-install carton form product that is attached to conventional formwork to block out areas of concrete where brick or stone is to be placed. It lowers the outside elevation of the concrete wall for the first course of brick or stone placement on what is referred to as a "brick ledge" or.

Concrete foundation wall reinforcing Building Performance

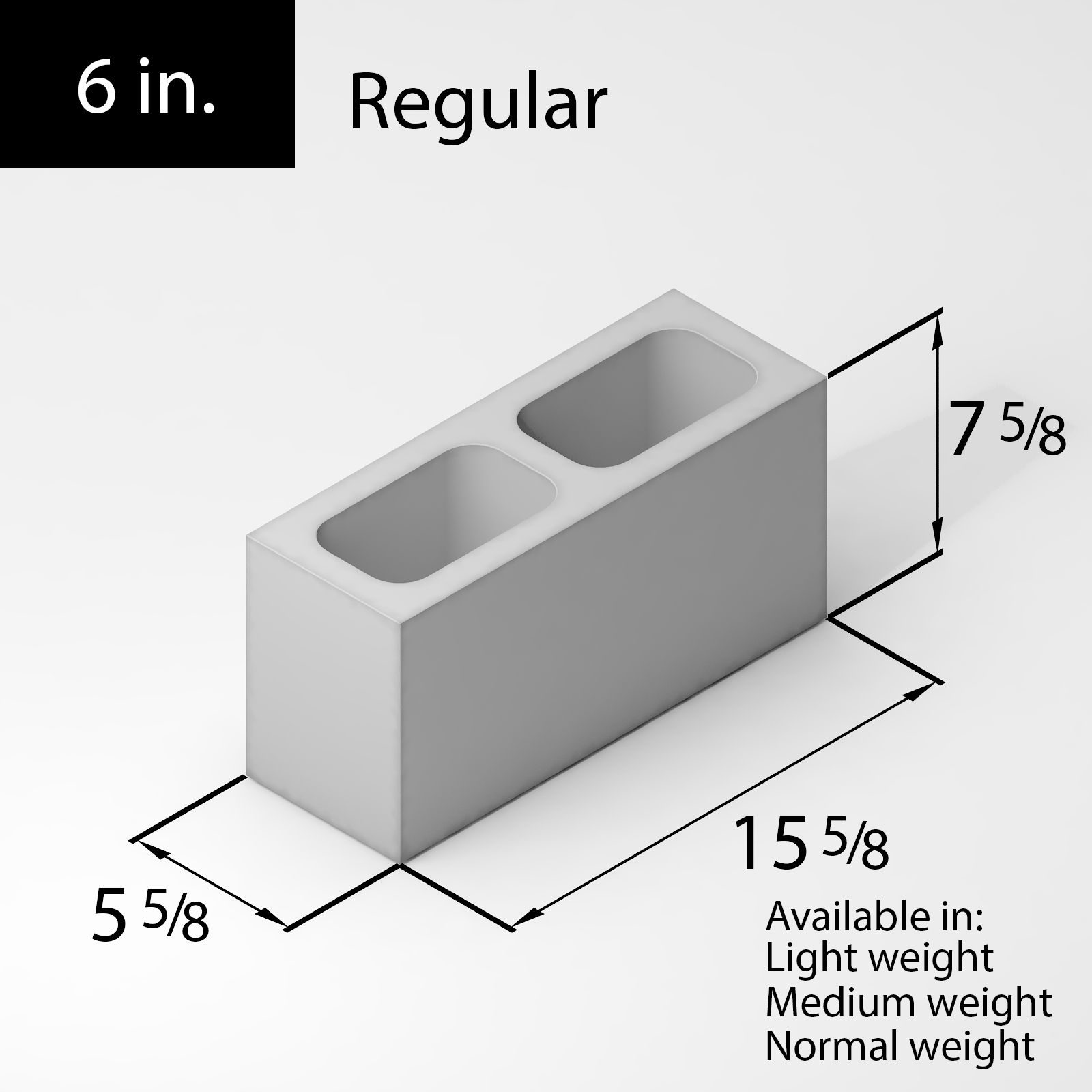

45° Beam Blocks The 45° degree blockout is used to create beam void for use of beams in bay areas. Heavyweight beam block ready to attach to your concrete form with a simple "C" clamp. For use with a standard 8" deep I-beam. Other sizes available. Drain Tile Blockout Drain Tile Blockout allows ease of installation of Drain Tile.

EPS Concrete blockout used to anchor prior to the concrete being

Buy 2000 for $6.00 each and save 5%. Buy 5000 for $5.68 each and save 10%. Size. Add to Cart. Product Description. The Double Tee Stem Blockout forms an opening 3" x 5-3/4" through the stem of the double tee to provide a clean, consistent opening for electrical and plumbing service. The Chamfered profile fits chamfered forms in a range of stem.

How to Lay Concrete Block Elston Materials, LLC

EPS block outs are used in place of, or in-conjunction with, wood and steel concrete forms. It can be difficult to create precise shapes and formations with a traditional concrete form. EPS can help solve this challenge when it is used to create a physical barrier, or "block out," for the concrete.

Foam Blockouts For Concrete Shelba Fardo

Working as a carpenter at Ravenswood Gold mine expansion the concrete Blockout system was easy to setup and fast stripping time. There is no mess to clean up and we could use the Blockout system immediately again on the next set of pedestals.. The removal of the block out if installed correctly is quick , clean and effective. Removing.

Home Blockout Concrete

Formed Square (Diamond) Blockout The pavilions are available with a few types of concrete forms.

West Van concrete walls « home building in Vancouver

Concrete Block-Outs Concrete block-outs are typically made of EPS for tilt-up wall panels as well as vertical poured in place applications. The EPS has the necessary compression strength to handle the weight of wet concrete and the pieces are delivered to the job site pre-cut and ready to use.

The Benefits of Insulated Concrete Forms (ICF) Foundations TC Legend

1 Lb EPS Block Outs When this contractor in Brookfield, IL 60513 needed eps concrete block-outs for his project he contacted Universal Foam Products Customer Projects EPS Foam Used to Seal a Cylinder for a Concrete Pour EPS (expanded polystyrene), often referred to as Styrofoam, can be cut into almost any shape and size Customer Projects

Le Reve Concrete Blockout

By Concrete Construction Staff. What methods can be used for small blockouts in tilt-up panels? Short sections of voids or tubes, pipe, electrical conduit or tin cans do a fine job. Note: where the sleeve will be left in place it should be galvanized.

Polishing Contractors Should Address PourBacks, Trenches and Cutouts

CCB. Buy 1000 for $11.87 each and save 5%. Buy 2500 for $11.24 each and save 10%. Size. 7-1.2" x 8" x 8-1/2". Add to Cart. Product Description. Composite Connection Blockouts create voids in precast bridge decks to accommodate through-bolted or welded connections for composite deck performance. Evaluations available of cross sectional drawing.

Concrete Block Foundation Advantages and Disadvantages of Concrete

Wood Forms. Using wood to form concrete is the oldest, most common method. Plywood is used to form all types of projects from patios, sidewalks, and slabs for smaller structures. To create a concrete slab, a simple square is constructed by screwing or nailing plywood and 2X4 lumber together. Stakes are driven into the surrounding sub-base.

Concrete Forms Geofoam, Styrofoam, EPS & Polystyrene Universal Foam

Concrete block-outs made of expanded polystyrene are common in the construction industry. They are lightweight, economical, and relatively easy to remove after the concrete is set. Whether being used to create a bolt pocket or anchors to secure an awning or canopy EPS is the material of choice among contractors.

EPS Concrete blockout used to anchor prior to the concrete being

The EPS block-out s can be installed with or without the bolts in place. For this project in Ephrata, Pennsylvania, the contractor was able to use 4" x 8" x 15" blocks of .9lb recycled EPS to secure the bolts in place prior to pouring the slab. Once the concrete sets up the EPS is removed and grout installed in the remaining opening.

Foam Blockouts For Concrete Shelba Fardo

$6.31 Double Tee Stem Blockouts - Chamfered SKU : C45 The Double Tee Stem Blockout provides through openings in double tee stems to accommodate electrical/plumbing service. Evaluations available of cross sectional drawing for sizing needs. Learn More $6.31 Double Tee Stem Blockouts - Chamfered Special Cut SKU : C45 SPCUT